Online monitoring of remaining Phosphine (PH3) levels in bulk carrier holds

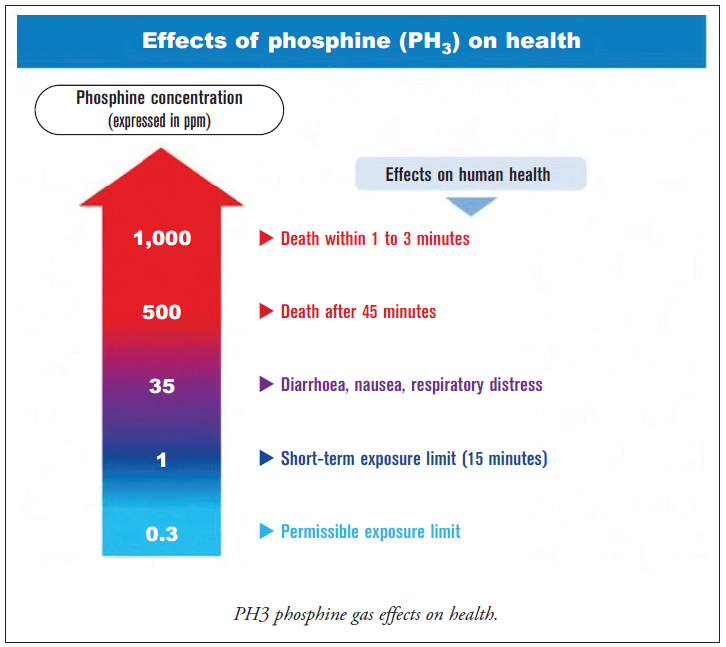

Phosphine PH3 is the most widely used fumigant in the world, ideal for fumigating mills, industries, factories, silos, warehouses, containers, among many others. In addition, it is the most recommended product for fumigation to control and prevent insect pests in food grains.

However, its use requires care to avoid exposing the health of workers who work directly in such places and hazard environments. For this reason, the Chilean Maritime Authority has imposed strict regulations requiring the permanent monitoring and recording of phosphine levels (PH3 in ppm) both in grains in the holds of ships and in silos or other storage places at port terminals.

Puerto Panul is the largest unloading terminal for food grains in Chile, located in the central area of that long country, facing the Pacific Ocean. The port unloads 3.5 million tonnes of food grains per year (wheat, corn and soybeans). It has therefore had to carry out a development project for the registration and monitoring in real time of the levels of phosphine of the more than 100 ships that it receives and must unload each year.

The system has been developed in partnership with the company ENCRYPTA CHILE, and consists of the installation of autonomous equipment which adheres magnetically to the top of the bulkhead of each of the holds of bulk carriers to be unloaded, or is installed in the silos where it may be stored or besides the conveyor belts where the grain pass thru.

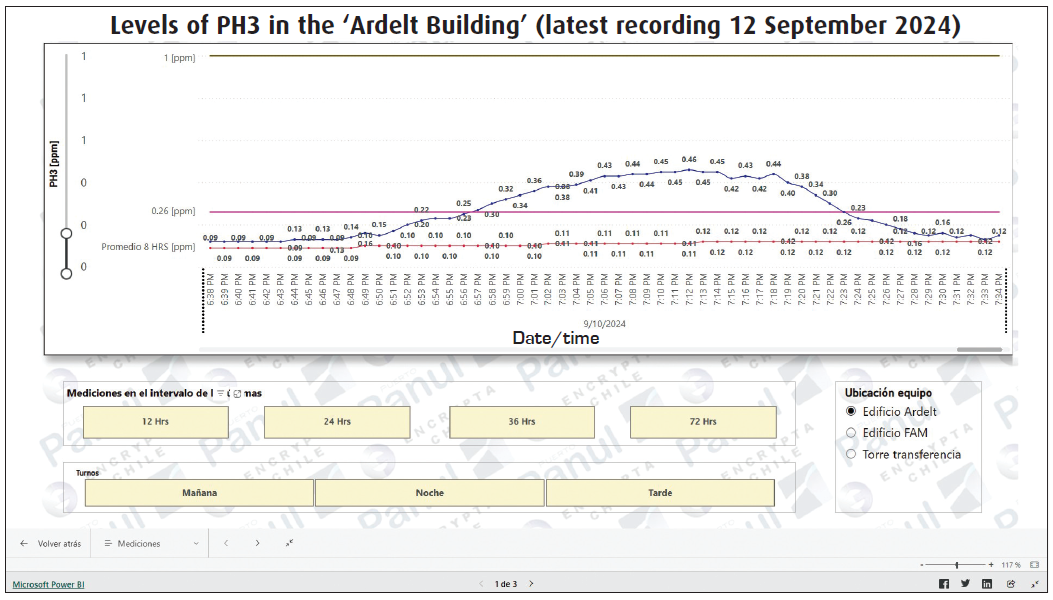

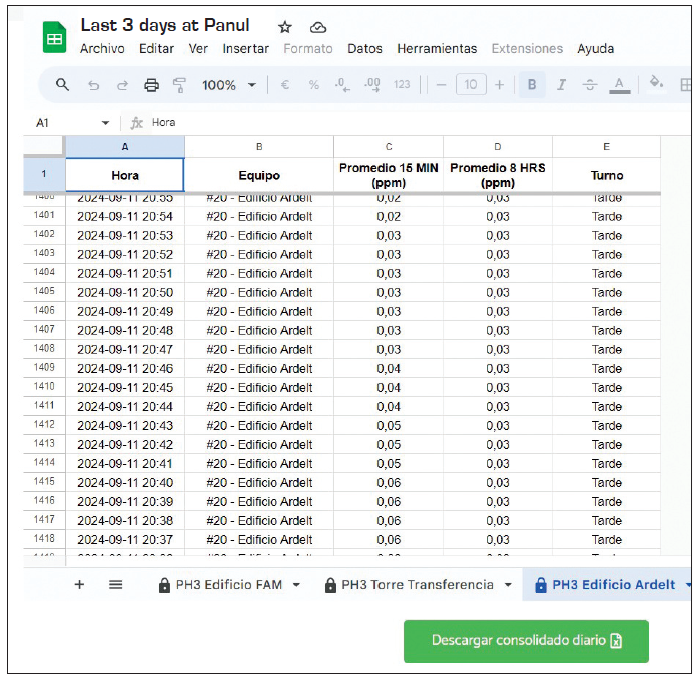

These sealed devices have Phosphine, Temperature and Humidity sensors. Data is collected and sent via GSM (Global System for Mobile Communications) minute-by-minute. The information from each device is recorded separately on a private access web pages, where historical records can be either reviewed in charts or downloaded spreadsheets. These devices have rechargeable batteries. It efficiently uses allow up to ten days of communication.

“We are very satisfied with the results obtained, because now we have real-time information on the levels of Phosphine that may still remain in residual form in the holds of ships, both those ships that are waiting on the line, as well as those that are being unloaded” says Cristian Valenzuela, CEO of Puerto Panul.

The system allows setting an alarm system, to calculate the average levels of Phosphine during the last 15 minutes (must not exceed 1.0ppm) or during the last eight hours (must not exceed 0.26ppm) according to the international standard also in force in Chile.

If at any time the levels of phosphine exceed the permitted ranges, the system automatically sends alert messages via SMS to the mobile phones of those responsible for the operation, as well as sending emails to the predetermined email addresses.

“This monitoring and alarm system gives us greater peace of mind in the care and safety of our workers, preventing them from being exposed to any hazard environment where there are levels of phosphine that may be bothersome or dangerous to their health. With these tools, in addition to meeting the demands of the authority, we can be more focused and take important operational decisions immediately,” concludes Valenzuela.